Industry Accidents: What History’s Worst Disasters Teach Us

Jan 29, 2026

Industry accidents are unplanned incidents in industrial environments that cause serious harm to workers, facilities, or nearby communities. In severe cases, they escalate into industrial disasters driven by hazardous materials, high-pressure systems, and complex operations.

In this blog, we examine why chemical plants, coal mines, oil rigs, and power plants remain high risk. Furthermore, we’ll explore the common causes of explosions, gas leaks, fires, toxic fumes, and worker fatalities, and how emerging safety intelligence tools, such as Canary Waves, are helping to surface risks earlier through everyday operational communication.

What Is an Industry Accident?

An industrial accident is an unplanned event that occurs during industrial operations and results in injury, loss of life, environmental harm, or damage to equipment and infrastructure. These incidents often involve hazardous materials, heavy machinery, or high-risk processes in which small failures can escalate rapidly.

Industrial accidents differ from large-scale industrial disasters in scope and impact. While an accident may affect a specific operation or work area, an industrial disaster extends beyond the site, causing widespread damage to surrounding communities, ecosystems, and public infrastructure.

Industrial accidents most commonly occur in high-risk settings such as industrial plants, chemical plants, oil platforms, and coal mines, where complex systems, volatile substances, and continuous operations leave little margin for error.

What Are the Most Common Industrial Accidents?

Across the world’s worst industrial disasters, the same accident types recur: small operational failures escalate into explosions, fires, and toxic releases, and into large-scale disasters when safety standards break down.

1. Gas Leaks and Gas Explosions

Gas leaks occur when flammable gases escape from their containment and accumulate in enclosed spaces. When gas is ignited, an initial explosion is often followed by fires, causing severe damage and killing workers in major incidents, including offshore disasters.

2. Dust Explosions (Coal Dust, Chemical Dust)

Dust explosions occur when fine particles, such as coal or chemical dust, become airborne and ignite. Common in mining accidents and industrial plants, these events spread rapidly through confined areas and have caused high death tolls in regions such as West Virginia when safety procedures failed.

3. Boiler and Methane Explosions

Boiler explosions are caused by pressure buildup or equipment failure, while methane explosions frequently occur in coal mines and oil operations. These incidents often involve multiple explosions, with fires and collapsed infrastructure trapping workers and increasing fatalities.

4. Fires Caused by Hazardous or Explosive Chemicals

Chemical fires typically result from improper storage or handling of hazardous substances. Materials such as ammonium nitrate fertilizer have driven some of the worst industrial accidents, including the Halifax Explosion and the Texas City disaster, where blasts destroyed entire city blocks. More of those two accidents later.

5. Toxic Chemical Exposure

Toxic exposure occurs when chemicals are released into the air, water, or soil, sometimes without an explosion. While less immediate, these incidents can escalate into large-scale industrial disasters, causing worker deaths, long-term health effects, and widespread community impact documented by major media outlets.

The World’s Worst Industrial Accidents in History

Below are some of the worst industrial accidents ever recorded, each shaped by safety violations and delayed response.

1. Bhopal Disaster (India)

The Bhopal disaster is widely considered the worst industrial disaster in history. A toxic gas leak at a pesticide plant released deadly chemicals into the surrounding city while workers and residents slept. Thousands were killed, with many more suffering long-term health effects. Subsequent investigations identified severe safety violations and violations of safety standards.

2. Halifax Explosion (Canada)

In 1917, a munitions ship carrying ammonium nitrate and explosives collided in a busy port city. The ship caught fire, followed by a massive explosion that destroyed entire city blocks. Flames spread rapidly, killing nearly two thousand people and injuring thousands more.

3. Texas City Disaster (United States)

The Texas City disaster began when ammonium nitrate fertilizer aboard a ship ignited. An initial explosion was followed by a second explosion that devastated the port and nearby industrial plants. Workers died across the site, and the death toll reached into the hundreds, making it one of the worst industrial accidents in U.S. history.

4. West Fertilizer Company Explosion (United States)

In West, Texas, a chemical plant storing ammonium nitrate exploded after a fire started on site. The explosion killed fifteen people, including first responders, and caused severe damage to the surrounding community. Later reports highlighted long-standing safety violations and failed inspections.

5. Phillips Disaster (United States)

The Phillips Petroleum plant explosion occurred after a release of flammable gas ignited, triggering two explosions and intense fires. Locked doors and inadequate emergency response trapped workers, resulting in multiple fatalities. Investigations cited failures in safety procedures and equipment design.

6. Deepwater Horizon Oil Spill (Gulf of Mexico)

The Deepwater Horizon industrial disaster began when methane gas ignited on an offshore oil rig, causing a massive explosion and fire. Eleven workers died, and crude oil spilled into the ocean for months, becoming one of the world’s worst environmental disasters. Coverage by the New York Times and Associated Press detailed systemic safety failures across the operation.

Mining, Energy, and Oil Sector Disasters

Mining, energy, and oil operations remain among the most high-risk industrial environments due to confined spaces, combustible materials, and high-pressure systems. When safety standards are violated, incidents in these sectors often escalate rapidly into fatal industrial disasters.

Notable mining and energy accidents in history include:

Upper Big Branch mine explosion (West Virginia, 2010): A methane gas ignition triggered an explosion that killed 29 miners. Investigations later cited widespread safety violations and ignored warning signs.

Monongah mining disaster (West Virginia, 1907): A massive coal dust and methane explosion killed more than 360 miners, making it one of the deadliest mining accidents in U.S. history.

Piper Alpha oil rig disaster (North Sea, 1988): A gas leak led to an explosion and fire on an offshore oil platform, killing 167 workers. Equipment failures and poor safety procedures were later identified as key causes.

Why Do Industrial Accidents Keep Happening?

Across the world’s worst industrial disasters, investigations point to a consistent set of failures that allow minor issues to escalate into explosions, fires, and loss of life in chemical, power, and energy operations.

Poor working conditions: Aging equipment and unsafe environments increase the risk that a fire will start or an explosion will occur, often leading to smoke inhalation and victims killed during subsequent fires.

Failed or ignored safety inspections: Corroded pipes, damaged hydraulic lines, and other known hazards were frequently overlooked before incidents where fire broke out, and explosions followed.

Weak safety systems and standards: Inadequate safety systems allow a single explosion to spread rapidly, turning localized failures into large-scale industrial disasters.

Improper handling of hazardous chemicals: Chemical plants and munitions facilities have experienced fires and explosions resulting from unsafe mixing and storage, with materials igniting and exacerbating damage.

Gaps in risk management: Poor oversight of routine operations, including crude oil handling and industrial transfers, has repeatedly allowed manageable risks to escalate into catastrophic events.

Preventing the Next Industrial Disaster with Real-Time Safety Intelligence

Preventing industrial disasters requires moving beyond reactive reporting toward proactive safety. Traditional safety procedures rely heavily on inspections and incident reports conducted after accidents, which limits their effectiveness in preventing accidents in fast-moving industrial environments.

In daily operations, early warning signs often emerge through routine communication, particularly radio chatter among frontline teams. When these signals are missed, small issues escalate into preventable incidents. Real-time awareness and the ability to transform everyday communication into safety intelligence are critical to identifying risks early and reducing the likelihood of catastrophic failures.

Canary Waves: Preventing Industry Accidents Through Early Safety Intelligence

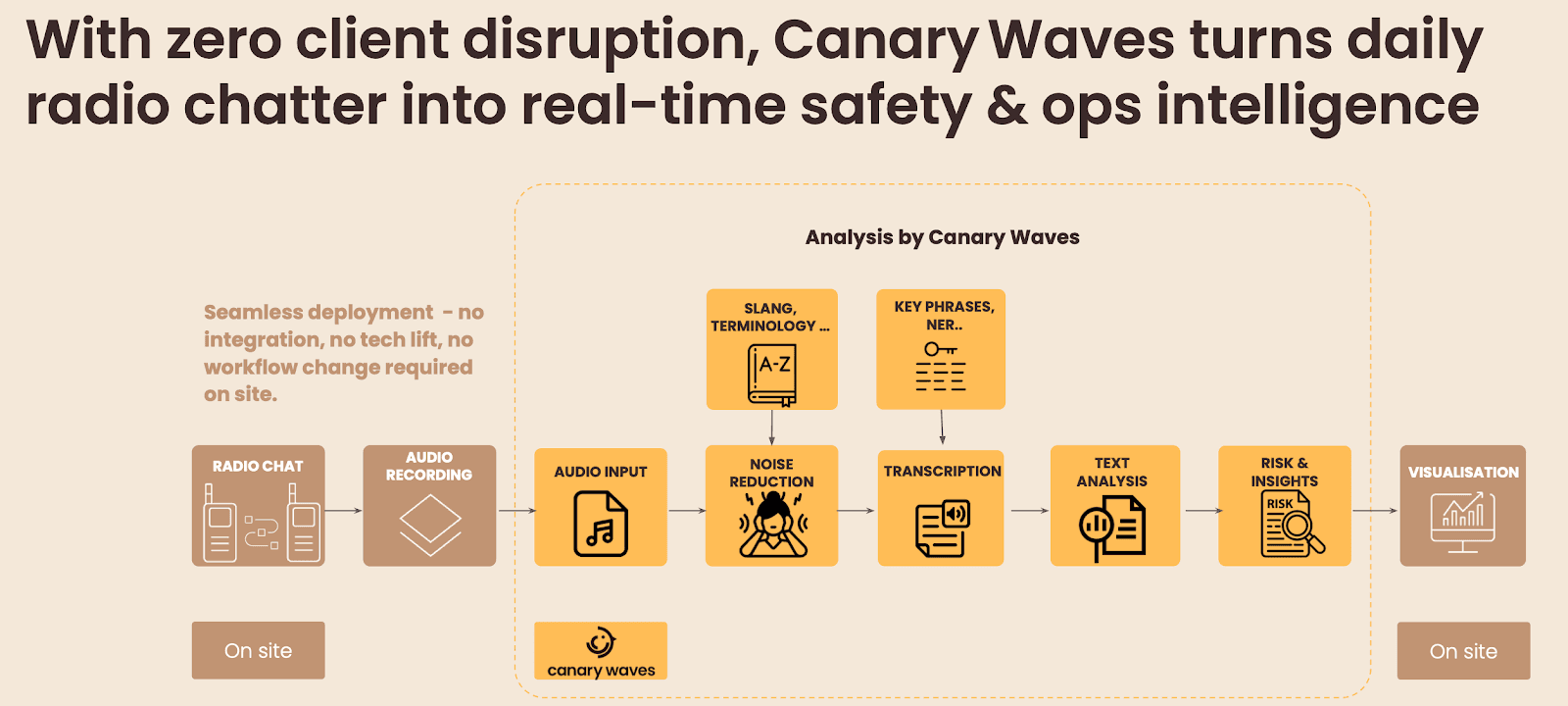

Canary Waves is built on the premise that many industrial accidents are preceded by warning signs present in daily operations. In high-risk environments such as mining, quarrying, energy, and heavy industry, such signals often occur within routine two-way radio communication and go unexamined.

Canary Waves delivers voice-to-data safety intelligence through real-time and delayed analysis of radio chatter, without changing how teams work. No new hardware is required, no complex integrations are needed, and existing workflows remain intact. Audio is transcribed, contextualized using site-specific terminology, and analyzed to surface risks, inefficiencies, and leading safety indicators.

This approach turns everyday communication into actionable insight, helping operators detect hazards earlier, reinforce safety procedures, and reduce the likelihood of fires, explosions, or fatalities. It provides a practical preventive layer for frontline operations, where preventing industrial accidents depends on recognizing risk before it escalates.

Interested in Canary Waves? Book your free consultation today.

Final Thought

Industry accidents rarely happen at random. History shows clear patterns in which known risks were overlooked, and early warning signs went unnoticed, turning preventable failures into disasters.

Today, modern safety intelligence enables earlier action. Solutions such as Canary Waves help surface risk signals hidden in everyday operations, giving organizations a practical way to break these patterns and prevent industrial accidents before they escalate.

Frequently Asked Questions

What causes most industry accidents?

Most industrial accidents result from poor working conditions, neglected safety inspections, inadequate safety systems, and improper handling of hazardous materials.

How can industry accidents be prevented?

Prevention requires proactive safety and early risk detection. Tools like Canary Waves help identify warning signs in daily operations before accidents escalate.